Innovative Tech Builds New Harbor in Stormy Water

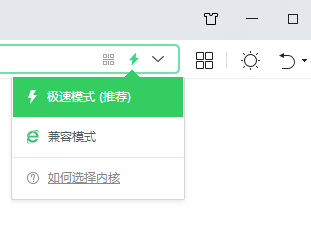

Aerial view of Ashdod New Port. (Photo provided by PMEC)

By HU Dingkun, YU Ziyue & LIANG Yilian

Ashdod, a vital port city on the eastern coast of the Mediterranean Sea in southern Israel, has seen a monumental upgrade of its infrastructure, with the construction of the epic Ashdod New Port project. Initiated in September 2014, and built by Pan Mediterranean Engineering Company (PMEC), a subsidiary company of China Harbor Engineering Company Ltd (CHEC), the port was delivered to the Israeli government ahead of schedule in May 2021. This ambitious infrastructure undertaking, backed by a 900 million USD investment, spans 2,363 meters of shoreline, including a 1,243-meter-long container terminal, and boasts an annual container throughput of two million TEUs.

The completion of this port significantly enhanced Israel's maritime capabilities, earning praise from Israeli Prime Minister Benjamin Netanyahu and former Transport Minister Yisrael Katz, who hailed it as one of the nation's "seven wonders."

The super platform conquers turbulent seas

Constructing the Ashdod New Port was not a small feat, as the region's sea conditions proved to be among the most challenging encountered by PMEC, which collaborated on this large-scale infrastructure project between China and Israel. The area's complex "long-period wave effect" and powerful surge waves closer to the coast presented severe obstacles, causing ships to experience drastic see-sawing, sometimes even reaching zero gravity. These factors significantly disrupted offshore construction, necessitating sheltering in the harbor during winter storms when wave heights could exceed 10 meters.

To tackle this challenge, the construction team focused on building a breakwater to protect the port. The soft seabed required reinforcement to support the weight of the breakwater, however, traditional methods like excavation and embankments were impractical due to poor efficiency and safety. Innovatively, PMEC developed the world's first "super top lifting platform" designed for constructing "submarine gravel piles." This groundbreaking platform, supported by four adjustable legs that could withstand turbulent waves, injected gravel into the seabed to create thousands of densely spaced piles, providing a solid foundation for the breakwater.?

"The development and utilization of this platform significantly expanded the construction window, improving efficiency and safety, leading to the early completion of the project and saving millions in costs," said Liu Dongbing, general manager of PMEC, adding that this achievement was recognized with one national invention patent and seven papers in China's core journals, along with many awards from their parent company.

Transforming Offshore Construction into Onshore Construction

The long-period wave effect also posed challenges to other offshore construction tasks, such as building wharf steel pipe piles. To address this, the project team introduced the concept of "transforming offshore construction into onshore construction." They utilized an innovative piling technique. The method involved placing a hydraulic pushing pile platform directly on the already installed steel pipe piles, unaffected by wind and waves, essentially converting the sea construction into a land-based process.

Inspired by bridge construction principles, this method significantly increased piling efficiency compared to traditional processes, reducing the construction period by eight months and saving millions of dollars. Given its success, this technology has been implemented in other projects by PMEC, according to Liu.

Advancing Green Development through Technological Innovation

PMEC is committed to scientific and technological innovation for green and sustainable development. Throughout the Ashdod port project, they optimized the design, employed advanced environmental protection facilities, and implemented measures to minimize the environmental impact on the nearby sea and the surrounding city.

For instance, in the "change the bottom" project of the sea wall, PMEC's approach of using seabed gravel pile construction was more environmentally friendly than traditional excavation and backfill methods, significantly reducing sea pollution. Furthermore, protective measures were implemented during dredging to prevent impacting surrounding waters, and the project team continuously monitored environmental indicators such as turbidity to ensure adherence to high standards of environmental protection.

The project stands as a testament to overcoming complex challenges with innovative solutions. This remarkable achievement not only strengthens Israel's maritime infrastructure but also exemplifies the importance of technological innovation in achieving sustainable development and preserving the environment. China's instrumental role in building Ashdod's new harbor reflects the power of technical capabilities and creativity in shaping a more connected and advanced world.