Inflatable Silos Embark on Low-carbon Grain Storage

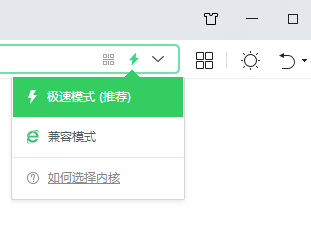

Photo shows inflatable grain silos built in Chengdu, capital of Sichuan province. (PHOTO: SINOGRAIN)

By?Staff?Reporters

Grain storage is well recognized as a vital part of the marketing, distribution and food security system.

To improve grain storage capacity, four giant grain silos were built in Chengdu, capital of Sichuan province. With a height of 36.1 meters and a diameter of 23 meters, each silo can store 7,500 tons of grains, equivalent to the annual consumption of 70,000 adults.

Technological transformation

The grain silos in Chengdu have applied a combined structure of inflatable membranes, steel and concrete. Inflatable silos are comparable to conventional ones in construction, but boast nearly 30 percent energy savings in operation, according to developer China Grain Reserves Group (SINOGRAIN).

The inflatable grain silo was innovated from the transformation of coal storage technology. In 2017, an inflatable membrane reinforced concrete spherical silo from China National Coal Group (China Coal) made its debut at a state-owned enterprises (SOE) innovation exhibition in Beijing, drawing attention from the SINOGRAIN delegation.

Adopting the novel construction technology and a special structure designed for excellent air-tight thermal insulation performance, greatly reducing energy consumption has the company's researchers wondering if the same technology could store grain.

However, grain storage is more complicated than coal, as it requires consistent temperatures below 20℃ and stable humidity and the walls of the silo must be smooth. These challenges were the tip of the iceberg, said Yu Pengbiao, director of the Research and Design Center of SINOGRAIN Chengdu Grain Storage Institute. He added that such technological transformation cannot be accomplished by a single enterprise, instead, it asks for multi-field cooperation. Thus, SINOGRAIN and China Coal, two central SOEs, jointly set up an R&D team for the inflatable grain silo in 2017.

Innovative research method

Xue Fei joined the research team after finishing graduate school. He was excited to be exposed to such an important project right after graduation. Soon, Xue found challenges came one after another.

"For example, the inflatable membrane structure consists of three main layers — polyester, polyvinyl chloride, polyvinylidene fluoride. What is the appropriate thickness deviation rate for each layer? How to avoid deformation of the structure after inflation?" Xue said to S&T Daily.?

After numerous discussions with experts in various fields from institutes and universities, the R&D team realized that to transform the coal silo into grain silo, even the most fundamental part -- silo body configuration -- must be redesigned.

To shorten the R&D cycle, a dual research model was applied. On the one hand, smaller "experimental silos" are built to carry out the simulation tests, and on the other hand, the theory is demonstrated on the software.

The design of this inflatable grain silo was like starting from scratch, said Li Lijun, engineer from China Coal. Li told S&T Daily that in four years, the team has built three "experimental silos" to compare the performance of parameters from different designs. Through this, many parameters have been confirmed in a fairly short time.

Finally, in March 2021, as a key project of SINOGRAIN, the inflatable membrane reinforced concrete dome grain silos in Chengdu were officially launched.

A good start

"Open the valve, start the fan, inflate and pressurize" -- after a series of steps, the project's first dome grain silo stood up in 105 minutes on June 7, 2022.

"After the pressure test, I'm sure the air tightness of the inflatable grain silo is the best that I've ever seen," said Sun Huinan, director at Zhengzhou Grain Machinery Quality Supervision, Inspection and Testing Center of National Food and Strategic Reserves Administration.

The air tightness of the inflatable silos is more than nine times the national standard, which translates to excellent thermal insulation performance and less energy consumption.

Seeing the data, Yu could not restrain his excitement. "We never thought of giving up in face of various difficulties during the R&D process because we knew it's significance to the country's food security!"

In the next step, the inflatable grain silo will be promoted in the grain storage industry. From zero to one, the effort of scientists and engineers has laid a solid foundation for countless more advanced grain silos in the future.